Hi Rodolphe,

I had a feeling maybe you are an engineer, with all your attention to detail and exactness. LOL Just curious, what is your engineering specialty?

Just curious, what is your engineering specialty?

Here's a link to the welding rod I use on all my projects. It's the R60 grade JB recommended in all his videos. https://www.mscdirect.com/product/details/59802314?rItem=59802314

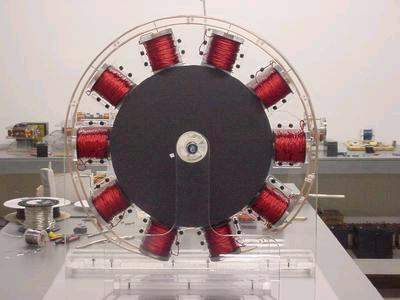

The R value of the rod specifies the tensile strength, which is a result of it's alloying content and is pretty standardized in the U.S. I cut them to maybe 3mm longer than the spool and then paint them with acrylic black paint to help increase resistance between them and reduce eddy currents. After they dry I pack them into the spool as tightly as possible, driving in the last 2 or 3 with a hammer. Next I put supper glue on the ends of the rods until it soaks all the way through to the bottom end. And lastly, I grind the rod ends flush with the ends of the spool to get the copper wire turns as close as possible to the end of the core.

As for the base resistors, if you have resistors at 100.1 ohms and 99.9 ohms that's .2 ohms difference or expressed as percentage .2% difference. If you have 470 ohm resistors with one at 470.1 and one at 469.9 with .2 ohms difference that's only .2/470 or .04255%. It's much easier to get a good match with higher resistance values. And for some reason, using fixed resistors in each branch that are near the total required value, with only a low value pot, seems to produce a more stable circuit than one that uses a larger value pot. The main base resistance remains more closely matched with only a small value tuning pot. Plus pots are less stable than fixed resistors and will sometimes drift when in use.

As for the MJL21194 transistors available, they are not all created equal in quality. Some of the cheap Chinese ones on E-bay are very low quality and have a high failure rate. Even when closely matched, they can still cause problems with performance and reliability. Be sure to use only ones from a reputable manufacturer and trusted supplier. Since I didn't want to buy a hundred or more transistors to get a good match, I just ordered them from Teslagenx in the kit along with the matched resistors.

Gary Hammond,

P.S. There's one other little thing I forgot to mention before. When I first ran the test that I reported on my home page, I had the charge battery negative connected directly to the negative of the primary batteries without going through the isolation diode. This gave the best results. I added the isolation diode at a later date which dropped the COP from 1.25 to about 1.13 as best I remember. When the batteries are less than .6 volts apart, which is the forward voltage drop of the output diodes, they don't self equalize when the negatives are connected together.

Adding the isolation diode raises this to 1.2 volts required to self equalize, which allows for a greater voltage difference between the primary and secondary. It also introduces more total resistance and a longer charge time.

I had a feeling maybe you are an engineer, with all your attention to detail and exactness. LOL

Just curious, what is your engineering specialty?

Just curious, what is your engineering specialty?Here's a link to the welding rod I use on all my projects. It's the R60 grade JB recommended in all his videos. https://www.mscdirect.com/product/details/59802314?rItem=59802314

The R value of the rod specifies the tensile strength, which is a result of it's alloying content and is pretty standardized in the U.S. I cut them to maybe 3mm longer than the spool and then paint them with acrylic black paint to help increase resistance between them and reduce eddy currents. After they dry I pack them into the spool as tightly as possible, driving in the last 2 or 3 with a hammer. Next I put supper glue on the ends of the rods until it soaks all the way through to the bottom end. And lastly, I grind the rod ends flush with the ends of the spool to get the copper wire turns as close as possible to the end of the core.

As for the base resistors, if you have resistors at 100.1 ohms and 99.9 ohms that's .2 ohms difference or expressed as percentage .2% difference. If you have 470 ohm resistors with one at 470.1 and one at 469.9 with .2 ohms difference that's only .2/470 or .04255%. It's much easier to get a good match with higher resistance values. And for some reason, using fixed resistors in each branch that are near the total required value, with only a low value pot, seems to produce a more stable circuit than one that uses a larger value pot. The main base resistance remains more closely matched with only a small value tuning pot. Plus pots are less stable than fixed resistors and will sometimes drift when in use.

As for the MJL21194 transistors available, they are not all created equal in quality. Some of the cheap Chinese ones on E-bay are very low quality and have a high failure rate. Even when closely matched, they can still cause problems with performance and reliability. Be sure to use only ones from a reputable manufacturer and trusted supplier. Since I didn't want to buy a hundred or more transistors to get a good match, I just ordered them from Teslagenx in the kit along with the matched resistors.

Gary Hammond,

P.S. There's one other little thing I forgot to mention before. When I first ran the test that I reported on my home page, I had the charge battery negative connected directly to the negative of the primary batteries without going through the isolation diode. This gave the best results. I added the isolation diode at a later date which dropped the COP from 1.25 to about 1.13 as best I remember. When the batteries are less than .6 volts apart, which is the forward voltage drop of the output diodes, they don't self equalize when the negatives are connected together.

Adding the isolation diode raises this to 1.2 volts required to self equalize, which allows for a greater voltage difference between the primary and secondary. It also introduces more total resistance and a longer charge time.

Comment