the closer a magnet is to a coil, the more of it's gauss "cuts" across the coils surface area and the closer it is the stronger the area of gauss is that interacts the coil. for a DC motor it is usually a brushed commutator that switches the windings polarity first attracting then repelling to allow the rotor to spin inside the permanent magnet field. the window motor is powered by a pulse, first one way, then the other, the switching of the circuit acts as a brush commutator in the rotor. its a pulse switched DC motor. the dwell (on time) and timing determine the speed and torque of a window motor.

here are my thoughts, this is not gospel truth just what I have read and observed..

a window motor runs best under load at 2/3 of its unloaded speed. this can be modified somewhat by what kind of magnet and core you use. a torque window motor needs an iron or steel core, a speed window motor uses an aluminum core.

the more powerful the magnet the more current it will draw to run, it needs to push that rotor away and the bigger the magnet the more force you will need to get it past. the recovery is also better with a more powerful magnet. (hence my experiment with the big neo mags on the other thread)

your best way to start is with 20 or so gauge wire, you can run more than 1 strand in parallel to drop the resistance of the coil. it really depends upon so many factors. the more turns you have the higher the field of the coil, so look for a coil between 1 and 3 ohms. if you settle on a 1 ohm strand you can either do a longer winding or parallel 2 or 3 with higher turns to bring the resistance down. its a balance of wire size, turns and length.

the full bipolar circuit is the way to go for driving, with a Hall sensor and timing disc.

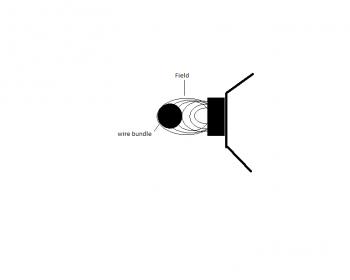

take a screwdriver and slowly move it into the magnet. when you feel the screwdriver begin to interact with the magnet, that is where you want the back edge of your coil wire bundle.

Tom C

here are my thoughts, this is not gospel truth just what I have read and observed..

a window motor runs best under load at 2/3 of its unloaded speed. this can be modified somewhat by what kind of magnet and core you use. a torque window motor needs an iron or steel core, a speed window motor uses an aluminum core.

the more powerful the magnet the more current it will draw to run, it needs to push that rotor away and the bigger the magnet the more force you will need to get it past. the recovery is also better with a more powerful magnet. (hence my experiment with the big neo mags on the other thread)

your best way to start is with 20 or so gauge wire, you can run more than 1 strand in parallel to drop the resistance of the coil. it really depends upon so many factors. the more turns you have the higher the field of the coil, so look for a coil between 1 and 3 ohms. if you settle on a 1 ohm strand you can either do a longer winding or parallel 2 or 3 with higher turns to bring the resistance down. its a balance of wire size, turns and length.

the full bipolar circuit is the way to go for driving, with a Hall sensor and timing disc.

take a screwdriver and slowly move it into the magnet. when you feel the screwdriver begin to interact with the magnet, that is where you want the back edge of your coil wire bundle.

Tom C

Comment